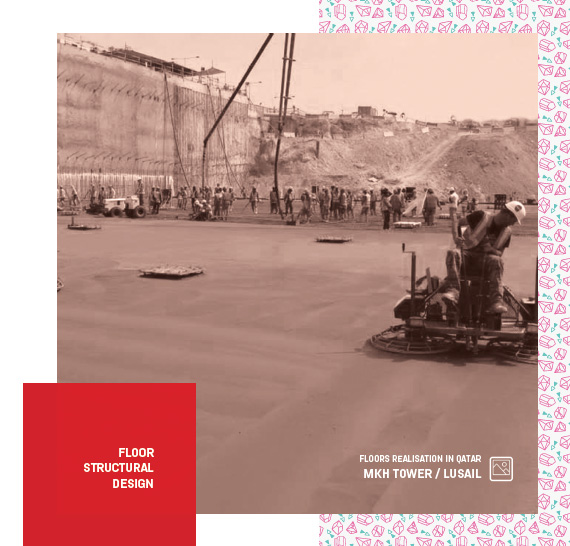

STRUCTURAL

DESIGN

The proper structural design is one of the most critical aspects of the project and it greatly influences the price of the floor.

That is why we have dedicated group of engineers focusing only on floor structural and technological properties. Thanks to that we can safely optimize all fundamental parameters such as: slab thickness, type of reinforcement (steel or synthetic), type of surface finishing (cement- mineral, epoxy or polyurethane) or dilatation systems.

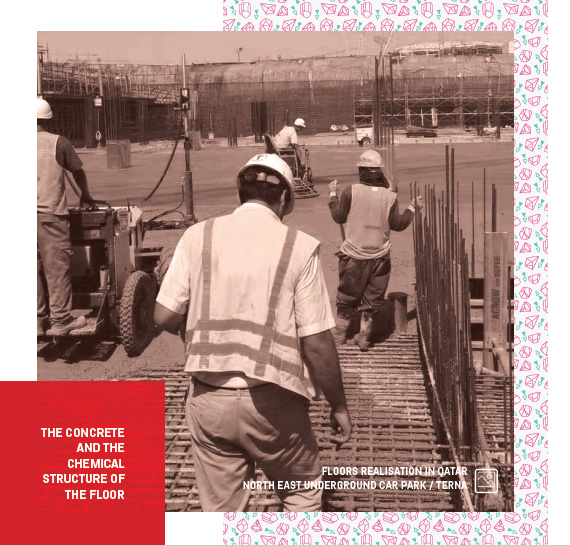

STRUCTURE OF

THE FLOOR

Consequences of using inexperienced contractors, neglecting this aspect of floor construction could prove to be catastrophic.

To reassure our customers, PAMFLOORS cooperates with the largest concrete laboratory in Poland belonging to BASF. Our engineers, under the BASF supervision, develop advanced recipes for concrete so it achieves the desired mechanical as well as specific properties requested and expected by the customer, such as: flatness, resistance to abrasion, and lack of cracking or delamination. In order to achieve this, we use different kinds of additives and chemical additions.

Those are added during the concrete production process – their type, quantity and the method of adding them are parts of design plan of PAMFLOORS.

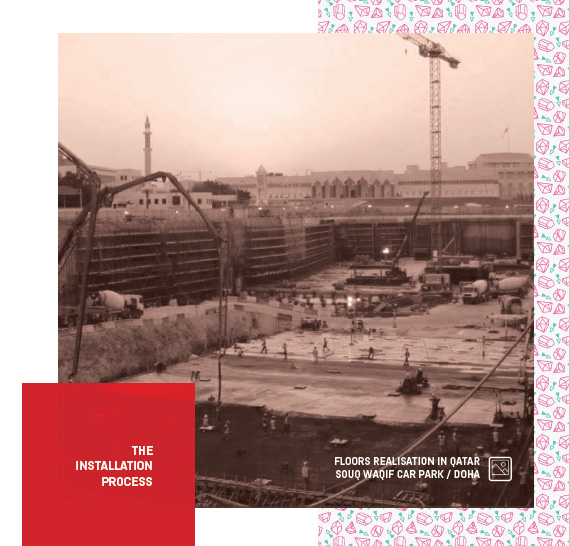

THE INSTALLATION

PROCESS

This aspect is the decisive factor for the success of the entire job. It is dependent on the correct choice of machinery (a virtual production line).

Thanks to the PAMFLOORS most modern technical solutions it is possible to reach the limits of technology and efficiency during processing of concrete. Computer controlled laser leveling of floor surfaces, while at the same time using a very effective vibrating technique, finishing with hydrostatic ride-on trowels (helicopters), applying sealers with super effective pumps, or finally early cutting of the flooring – this is just a few among many techniques used by PAMFLORS in the process of industrial flooring installation. This allows us to reduce human error to the minimum and leave the installation of the floor in the hands of only a small group of professionals: operators and technicians, whose qualifications are constantly being raised through constant training, including in the H&S.

UP TO: 5 000m2 / ONE TEAM SHIFT 36 000m2 / ONE TEAM WEEK with the highest quality regime

ET FLOOR

TECHNOLOGIES

It is worth noticing that many elements of the equipment used in Qatar have been modified to properly function in the local climate.

In order to produce best quality industrial flooring and at the same time offer very competitive price, all the elements have to be optimized to work with each other seamlessly and that is what PAMFLOORS does exceptionally well. This is the reason why our technicians visited a number of concrete plants in Doha and analyzed available aggregates. Also we brought all types of cement available in Qatar to our labs in Europe and studied them. We performed a market analysis of concrete additives including their chemical makeup and their real influence on the process of floor installation. On the basis of the analysis in our labs we optimized the slab surface hardener – a mineral and cement topping – including chemical additives, the type of cement and additional minerals. We selected the reinforcing material, both synthetic and steel, to ensure the stability of the floor structure but also the achieve the best results connected with the curing of the concrete, especially the reduction of structural tension.